Cabinets

How do you select cabinets for your bathroom and kitchen? Typing “Cabinets” in Google returns over 2.3 billion results! That’s not helpful! How a cabinet is made is the most important consideration. There are basically 3 types of cabinets. These are solid wood, particle board (Melamine Faced Chipboard or MFC), MDF and HDF (Medium-Density Fibreboard and High-Density Fiberboard).

How do you select cabinets for your bathroom and kitchen? Typing “Cabinets” in Google returns over 2.3 billion results! That’s not helpful! How a cabinet is made is the most important consideration. There are basically 3 types of cabinets. These are solid wood, particle board (Melamine Faced Chipboard or MFC), MDF and HDF (Medium-Density Fibreboard and High-Density Fiberboard).

Cabinets are either custom made or manufactured. If you are looking for strength, durability, beauty, and customization, custom cabinets are for you. However, if you are budget conscience and durability, strength, and flexibility are not important, manufactured cabinets are for you.

Manufactured cabinets come preassembled or ready to assemble (RTA). Almost 70% of all manufactured cabinets sold in the United States come from China, Vietnam, Mexico, and Canada. Over 60% originate in China or Vietnam. Cabinets made in the far East employ materials that use significant amounts of Formaldehyde. Formaldehyde is a toxic and dangerous carcinogen gas.

What is the difference in these materials when considering cabinets?

|  |  |

|  |  |

| Solid Wood | MDF and HDF | Particle Board (MFC) |

Solid Wood Cabinets

Solid wood cabinets are derived from timber-yielding trees. Logs obtained from felled trees are cut into various board sizes. Wood is much stronger than MDF, HDF, and particle board. Wood has natural, enduring beauty and lasts a lifetime. Solid wood can be shaped, stained, and painted to virtually any preference. It takes a much crisper edge than MDF or HDF.

Oak and hickory are some of the strongest, most reliable wood species available for custom cabinets. They generally cost more, but they mix beauty with long-lasting reliability. If you want cabinets that resist impacts and warping, these two would be good choices. The best wood for staining combined with strength is select maple.

Natural wood contains no harmful formaldehyde. This is my number one choice for cabinet doors, drawers, and fronts. You can’t beat the lasting beauty, quality, strength, and safety of real solid wood.

Natural wood contains no harmful formaldehyde. This is my number one choice for cabinet doors, drawers, and fronts. You can’t beat the lasting beauty, quality, strength, and safety of real solid wood.

MDF and HDF Cabinets

MDF and HDF takes a crisper edge than particleboard (MFC). Made from very small wood fibers (almost like flour). This engineered lumber product uses urea-formaldehyde resin adhesives to bond the fine sawdust together. Formaldehyde is suspected of being a carcinogen, and MDF and HDF have some of the highest concentration of urea-formaldehyde adhesives out of all the engineered wood products that use it. Water and heat will quickly destroy MDF and HDF. Thermofoil finishes tend to separate from MDF and HDF. Both are susceptible to yellowing.

Particle Board Cabinets

Particle board (MFC) is manufactured by mixing sawdust, wood chips, and scraps with powerful formaldehyde resins. Formaldehyde is a a toxic gas. Prolonged exposure to high concentrations of formaldehyde presents a health hazard. Particleboard is made from larger, coarser fibers. It tends to chip out when screwed, nailed, shaped, and routed. Water and heat will quickly destroy particle board.

For additional information on cabinet building materials, see Particle Board vs Plywood Cabinets.

Finishing Cabinets

Cabinets can be finished using a range of applications. For solid wood cabinets, the most important part of finishing is the grade of the wood and sealing prior to applying the final finish. For particle board, MDF, and HDF, the density of the product, sealing, and primer used are the critical parts.

Wood Cabinets

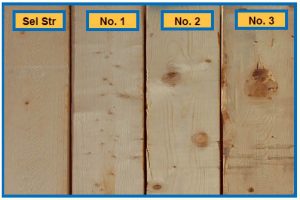

Wood cabinets are finished clear, stained, or painted. The quality and durability depend on the grade of wood used. There are 7 grades of hardwood.

- Firsts and Seconds (FAS) – This is the best and most expensive grade. FAS hardwoods have 83-1/3 percent of clear face cuttings. The boards are graded from the poorer face side. FAS is ideal for fine furniture, cabinetry, and applications where clear, wide boards are needed.

- FAS One Face (F1F) – The same as FAS except the board is graded from the better face side.

- Selects (SEL) – The face side is FAS while the back side is No. 1 Common. Select boards have 83-1/3 percent clear face cuttings on the best side. Select is an excellent and cost-effective substitute for FAS when only one good face is required.

Maple FAS (both sides); F1F & SEL – Face Side

Maple F1F & SEL – Back Side

- 1 Common – A typical thrift or “shop” grade. These boards yield 66-2/3 percent clear face cuttings on the best side. This grade of wood delivers good

value when small pieces are used.

value when small pieces are used. - 2A & 2B Common – Boards yield 50 percent clear face cuttings on the best side. Suitable for some paneling and flooring applications.

- 3A Common – These boards yield 33-1/3 percent clear face cuttings on the best side. This is an economical choice for rough utility applications such as crates, palettes, fencing, etc.

- 3B Common – Hardwood with this rating yields 25 percent clear face cuttings on the best side. Applications are the same as No. 3A Common.

The important thing to remember when paying for wood cabinets is to make sure you are getting Select or better. This is especially true if your cabinets will be stained or have a clear finish.

MDF, HDF, and Particle Board Cabinets

MDF, HDF, and MFC (Particle Board) cabinets can be finished in one of two ways. The first is paint. The second is thermofoil. Paint can only be used effectivly on MDF and HDF. When painting, both must be sealed and primed using high-quality products. The primer is a heavy bonded primer that applies thick. This thick primer fills and hides all the imperfections. The actual paint is typically one or two very thin coats or a thin coat of tinted lacquer. Tinted lacquer is common on white MDF and HDF cabinets. Therefore, painted, or lacquered MDF and HDF cabinets scratch, dent, and nick easily. It’s nearly impossible to touchup either of these cabinet types and make them look new again.

MDF, HDF, and MFC (Particle Board) cabinets can be finished in one of two ways. The first is paint. The second is thermofoil. Paint can only be used effectivly on MDF and HDF. When painting, both must be sealed and primed using high-quality products. The primer is a heavy bonded primer that applies thick. This thick primer fills and hides all the imperfections. The actual paint is typically one or two very thin coats or a thin coat of tinted lacquer. Tinted lacquer is common on white MDF and HDF cabinets. Therefore, painted, or lacquered MDF and HDF cabinets scratch, dent, and nick easily. It’s nearly impossible to touchup either of these cabinet types and make them look new again.

MDF, HDF, and MFC cabinet doors do not hold screws and hardware securely and both tend to loosen and fall out. One of the major drawbacks to MDF, HDF, and MFC is their reaction to moisture. Water and moisture will cause these products to deteriorate rapidly.

Thermofoil

| Thermofoil | |

|  |

These cabinets have a heat activated, plasticized vinyl surface finish. The plastic material can take any shape. Thermofoil doors, cabinets, and drawers can be a solid color or made to look like real wood grain cabinets.

Thermofoil cabinets look and feel very similar to finished wood cabinets. They are available in all the same styles as wood cabinets. Many retailers and manufacturers use the terms Rigid Thermal Foil (RTF), Ready-To-Assemble (RTA), and Laminate Cabinets (LC) to describe thermofoil.

Particle board (MFC) cabinets often use a thin veneer on the front and back sides. Thin strips of wood veneer are applied to the sides of MFC cabinets using a process called “Edge Banding”. This further conceals the particle board. This also hides the particle board material on the sides and edges. Edge banding (thin wood strips – comes in a roll) give the appearance of real wood cabinets. It can be very deceptive.

Thermofoil applied over MDF, HDF, and MFC (particle board) cabinets, doors, and drawers are significantly cheaper (both ways) than real wood.

To the untrained eye, it is nearly impossible to tell the difference between solid wood and thermofoil cabinets. It is perfectly legal to call solid wood, MDF, HDF, and MFC cabinets, doors, and drawers “solid wood”. That low price estimate you received for solid wood cabinets is likely MDF, HDF, or MFC (particle board). Make sure you are getting solid wood cabinets, not the cheap junk. Make sure the person you are buying your cabinets, doors, and drawers from has a solid reputation for honesty and high moral and ethical standards.

Thermofoil over MDF, HDF, and MFC Cabinets

Environmental regulations make the adhesive properties in thermofoil less than satisfactory when applying to MDF, HDF, and MFC. Increasing numbers of customers who installed thermofoil doors, drawers, and cabinets are discovering their mistake. The most common product used to cover MDF, HDF, and MFC cabinet doors, drawers, and boxes is thermofoil. Why? It’s cheap – both ways! DAD’s Construction only uses solid wood for our cabinet doors, drawers, and face fronts. We use plywood on our boxes. With our cabinets, you never have to worry about everything falling apart. They are strong, durable, and beautiful!

Environmental regulations make the adhesive properties in thermofoil less than satisfactory when applying to MDF, HDF, and MFC. Increasing numbers of customers who installed thermofoil doors, drawers, and cabinets are discovering their mistake. The most common product used to cover MDF, HDF, and MFC cabinet doors, drawers, and boxes is thermofoil. Why? It’s cheap – both ways! DAD’s Construction only uses solid wood for our cabinet doors, drawers, and face fronts. We use plywood on our boxes. With our cabinets, you never have to worry about everything falling apart. They are strong, durable, and beautiful!

What about the Cabinet Frames (Boxes)?

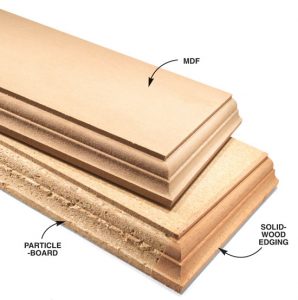

The picture on the right illustrates the four types of materials used to construct cabinet boxes. We’ve already talked about MFC (Melamine Faced Chipboard . . . particle board) and MDF (Medium-Density Fibreboard). HDF (High Density Fiberboard) is also an engineered wood product. Made from wood fiber extracted from chips and pulped wood waste. Using formaldehyde resin adhesives under immense pressure and heat, MDF and HDF takes its shape.

The picture on the right illustrates the four types of materials used to construct cabinet boxes. We’ve already talked about MFC (Melamine Faced Chipboard . . . particle board) and MDF (Medium-Density Fibreboard). HDF (High Density Fiberboard) is also an engineered wood product. Made from wood fiber extracted from chips and pulped wood waste. Using formaldehyde resin adhesives under immense pressure and heat, MDF and HDF takes its shape.

Look at the plywood. Notice how much thicker the wood laminate is on both sides. The laminate on MFC, MDF, and HDF is very thin. MFC, MDF, and HDF can’t compete with the superior strength and durability of plywood. Plywood is the best choice for cabinet boxes. Plywood does not soak up water and liquids like MFC, MDF, and HDF. This makes it less susceptible to damage. The grains in plywood makes it easier to stain.

Plywood gets its strength by bonding multiple layers of veneer together. These layers are called “plies”. Each layer is alternated 90 degrees from the layer beneath it and glued together. This layered construction is what gives plywood its strength. This process allows plywood to hold screws tightly. The multiple layers give each screw more holding power and strength.

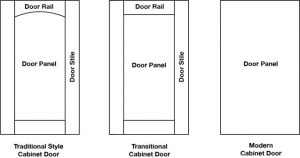

Are there different types of cabinet design?

Yes! These are Traditional, Transitional, and Modern.

Types of Cabinets

Traditional Style Cabinets

|  |

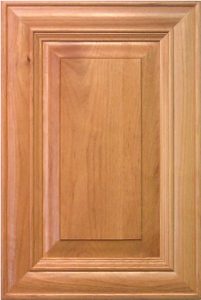

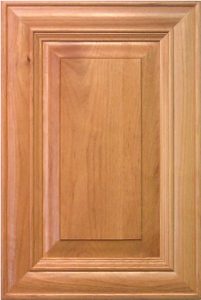

The classic traditional style cabinet has doors and drawers that have a raised panel design. Raised panel designs are very traditional – They always have a floating center panel outlined by a carved design. The center panels can be rectangular with sharper edges, rounded with softer features, or have a more arched appearance.

Transitional Style Cabinets

|  |  |

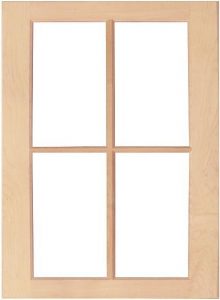

|  | Mullions are the dividing bars that separate glass panes in a door, much like those found in windowpanes. Any style cabinet can use mullions. |

There are three main options for these transitional style panels: Recessed, Shaker and Mullion. Not too historic or sleek, transitional cabinets are a mix of modern and traditional.

Recessed cabinet doors and drawers have a depressed center panel. This adds a more dimension and subtle detail to cabinets. These five-piece doors and drawers add elegance.

Shaker cabinets are one of the most popular cabinet options out there – and for good reason. Their five-piece cabinet door and drawer design with recessed center panels gives them a simple and versatile look.

Mullion cabinets have door panels with glass panes as their door panels. This gives complete transparency inside your cabinets. Mullion cabinet doors are ideal to use as a bookshelf or to hold glassware, beverages, and dining room essentials. Whatever items you decide to keep in these cabinets will be on full display. Adding strips of wood (moldings) to the glass panel gives them a more decorative aesthetic.

Modern Style Cabinets

|  |

Modern cabinets have flat doors and drawers. These are considered very European. There won’t be a rectangular/square frame around the door panel (no stile or rail). Using modern or ultra-modern hardware for this type of cabinet tends to be a great choice, given the sleek look of the cabinet door.

Examples of Cabinet Door and Drawer Styles

Below is a collage of cabinet door and drawer styles representing a mix of Traditional and Transitional design. This assortment provides an idea of how they might look together. Notice how a particular style can have multiple designs. The Shaker Fairfield and Tahoe use the same style, but each is a different design.

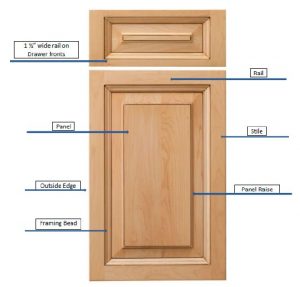

Anatomy of a Cabinet Door and Drawer

When selecting cabinets for your bathroom or kitchen, it’s important to understand the language. Cabinets constructed using solid real wood employ a 5-part process. Five-part doors and drawers mean they are constructed using 5 individual pieces. These consist of 2 stiles, 2 rails, and 1 panel. When assembled using dovetail construction, these are the strongest and most durable.

|  |

Always Hire a Reliable and Dependable Contractor to Remodel your Home

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom, kitchen, and full interior remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements.

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom, kitchen, and full interior remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements.

Rest assured that we will provide you with a detailed, by line-item contract. We will make sure that the contents of this agreement are properly and clearly communicated to you. If you have questions or need updates regarding your project, we will always answer your inquiries.

How Can I Receive More Information on Remodeling my Bathroom?

If you would like more information on enjoying the best bathroom, kitchen, and interior remodeling experience in Orange County, call Dan at (949) 380-0177 or at dan@dadsconstruction.com for a free in home consultation. DAD’s serves all of South Orange County California. This includes Lake Forest, Mission Viejo, Foothill Ranch, Portola Hills, Ladera Ranch, Irvine, San Clemente, Dana Point, San Juan Capistrano, Rancho Santa Margarita, Coto de Caza, Dove Canyon, Laguna Niguel, Laguna Hills, Laguna Beach, Newport Beach, and Aliso Viejo.

“Taking Care of Your Home . . . The Way We Would Our Own”

Daniel A. Derkum is the owner of DAD’s Construction. DAD’s is a leading South Orange County, California design-and-build remodeling and renovation Contractor. See https://www.dadsconstruction.com. © DAD’s Home Services & Construction, Inc. All Rights Reserved.

value when small pieces are used.

value when small pieces are used.